PRODUCTS / COMBUSTOR

Combustion Efficiency and Flare Emissions

Accord have developed Combustor - a dynamic process simulation model to calculate and monitor combustion efficiency of flaring operations, helping Operators visualise, understand and take action to reduce overall CO2e emissions.

Using minute-by-minute calculations of combustion efficiency, Combustor gives a near real-time view of the methane, CO2 and CO2e emissions using inputs of windspeed at the flare tip, and the composition of the flared gas. This accurate calculation shows flaring combustion efficiency can often be greater than the commonly used default of 98%.

Combustor Demo

Using our demo tool below, can you achieve a combustion efficiency greater than 98%?

Tweak the windspeed, hydrocarbon (HC Stream) and nitrogen (N2 Stream) sliders to see the impact.

Scroll down for suggested demo settings and for more details on the background research for this initiative.

This demonstration is designed to show the general effects of

changing the supplied parameters on the combustion efficiency and

emissions of a flare. The properties of the gas streams and the flare

are simplified for the purposes of the demonstration. In an operational Combustor implementation, live measured data is

used and the CHARM process modelling software allows us to accurately

model the flows on a minute-by-minute basis.

Windspeed

Generally the higher the windspeed, the lower the flare efficiency.

For reference,

2-3m/s = light breeze

8-10m/s = fresh to strong breeze

20m/s+ = gale of storm force winds

70m/s = category 5 hurricane

HC Stream

This is the flow rate of the hydrocarbon stream flowing into the flare. This stream is modelled as a methane-rich gas stream with a default Net CV of 48 MJ/kg

N2 Stream

A stream of inert gas used to purge the system and increase flow through the flare.

Try increasing windspeed using the windspeed slider. As the wind increases, the combustion efficiency drops. More methane and hence Carbon Dioxide Equivalent (CO2e) is emitted.

In this model a stream of inert Nitrogen (N2) is commingled with the flare gas stream. In many real-world flare systems, purges are present to ensure safe operation of the flare system and to increase flow rates through the flare.

If you increase the N2 flow rate, the combustion efficiency decreases and the CO2e emissions increase.

Increasing the N2 flow rate reduces the heating value of the flare stream. The exit velocity of the flare gas will increase but the reduction in heating value has a larger effect on the combustion efficiency and the combustion efficiency is strongly reduced.

Can understanding the effects of the flare and N2 flow rates and wind speed on flare combustion efficiency let us tune a flare to reduce the greenhouse emissions associated with the flare?

In some flow regimes, yes we can optimise CO2e. Where the combustion efficiency is being strongly depressed by high wind speed, sometimes we observe an increase in flow rate of hydrocarbons resulting in a lower rate of methane and CO2e release. One example of this can be observed in this demonstration model as follows:

Set wind speed to 30m/s, N2 flow rate to 0kg/h, hydrocarbon flow rate, 1kg/h (minimum setting).

Increase the hydrocarbon flow rate gradually.

Initially you will see the CO2e emissions increase. The flare is unlit and all of the methane in the flare hydrocarbon stream will be released to atmosphere. Once the exit velocity of the hydrocarbons is sufficiently high, the flare will be lit and further increases in hydrocarbon flow rate will result in decreased CO2e emissions.

At a hydrocarbon flow rate of around 130kg/h the optimum point is reached and further increases in flow rate will result in an increased CO2e emissions rate.

Accurate methane emissions

After carbon dioxide, methane is the most important greenhouse gas contributing to climate change. With an increasing focus on methane, operators are seeking to manage their flare activity to understand and reduce their methane emissions. The combustion efficiency of the flare is key to understanding how much unburnt methane is emitted but without an accurate calculation method Operators have typically used a default combustion efficiency of 98% (2% unburnt). In many cases, this over-estimates the methane emissions and Operators are seeking to better quantify them.

Accord have developed Combustor - a dynamic process simulation model, based on recent academic papers, that will allow oil and gas operators to calculate combustion efficiency to monitor and improve the efficiency of their flaring operations — thereby reducing their overall CO2e emissions. Combustor can be configured to calculate a minute-by-minute combustion efficiency giving a near real-time view of the methane, CO2 and CO2e emissions.

Working with a range of North Sea Operators and supported by the Net Zero Technology Centre (NZTC), this project is a fine example of the innovative approach we take — building upon the success of one good idea to realise another, and helping support operators as they pursue Net Zero targets in an industry that increasingly understands the importance of reducing methane emissions alongside CO2.

Powered by CHARM, Combustor will predict flare gas properties required to calculate combustion efficiency accurately. The efficiency calculation is transparent, peer-reviewed and referenced in OGMP 2.0 and the OGUK Methane Action Plan. Using the CHARM architecture, the calculations can be easily integrated into existing monitoring and control systems. This software solution provides significantly improved data on methane and overall CO2e emissions without the need for any on-site physical installations or additional metering.

More information, including details of Combustor field trials, can be found here: Quantifying the Combustion Efficiency and Emissions of Flare using Combustor - Project Summary

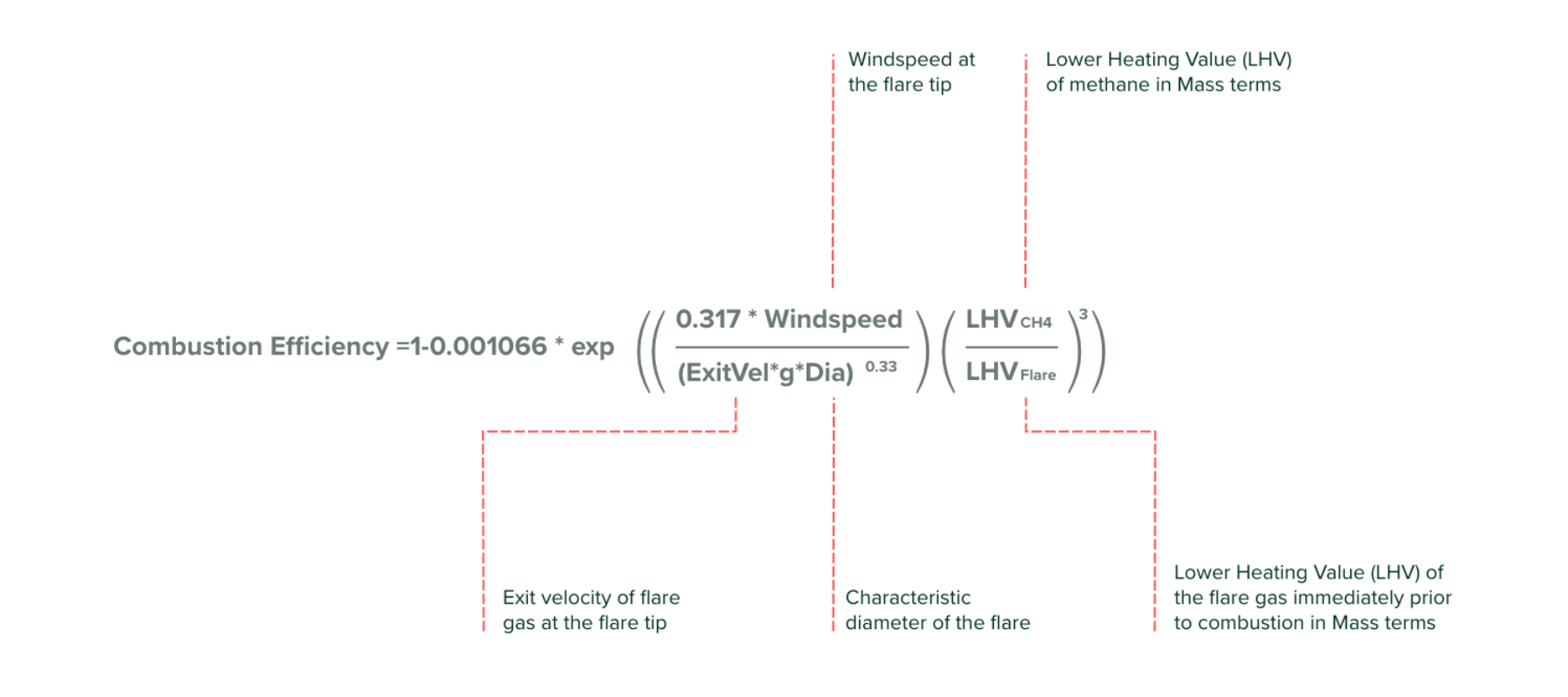

The UoA Algorithm

Combustor is based on the publicly available study published by the University of Alberta (UoA) in 2004. It provides a robust and repeatable methodology which has passed through rigorous academic scrutiny.

84x

Methane has 84 times the global warming potential of CO2 over 20 years

5

Operators collaborated with Accord on the NZTC project to develop Combustor

98%

Default combustion efficiency used by Operators when reporting flare emissions. Combustor helps Operators understand and optimise the real efficiency.

Combustor — At a Glance

Research Backed

Combustor’s combustion efficiency prediction is based on pioneering work done by research specialists at the University of Alberta, Canada.

Net Zero Targeted

Combustor applies the process modelling functionality of CHARM to flare efficiency, offering operators vital opportunities to reduce and control their emissions.

Integration-Ready

Based on the CHARM architecture, Combustor adheres to industry standards, with easily-maintained XML-based interfaces to ensure ongoing compatibility with existing and future systems, including flare measurement and plant control systems.

Accurate Compositions

Utilising the functionality already delivered by CHARM, the flare composition can be accurately predicted, eliminating the requirement for expensive sampling or online chromats.

Cost Effective

Calculating combustion efficiency using Combustor delivers results based on a proven model without the need for direct measurement.

Optimising Flaring Operations

With real-time calculation of combustion efficiency, Operators can optimise flaring activity to minimise overall emissions.

Valuable Insight for Emissions Trading

The North Sea Transition Authority (NSTA) updated their Flaring and Venting Guidance in June 2021 and recognise that flare combustion efficiency plays a key role in minimising greenhouse gas emissions resulting from flare activity. The NSTA Guidance states that “Operators should meter, monitor and manage their flare gas composition and flare combustion efficiency to ensure minimum greenhouse gas emissions resulting from flare activity”.

Combustor provides operators with an online, live calculation of combustion efficiency, and provides control feedback which can be used to improve the combustion efficiency of flaring operations and thereby reduce the overall emission rates of CO2 and Methane. As emissions legislation evolves, Combustor will be a vital tool, providing valuable insight and informing key business decision-making, particularly with regard to participation in ‘cap and trade’ systems.

“Combustor provides companies with a tool which will help to achieve level 4 Gold standard reporting under the OGMP framework.”

EXPLORE MORE